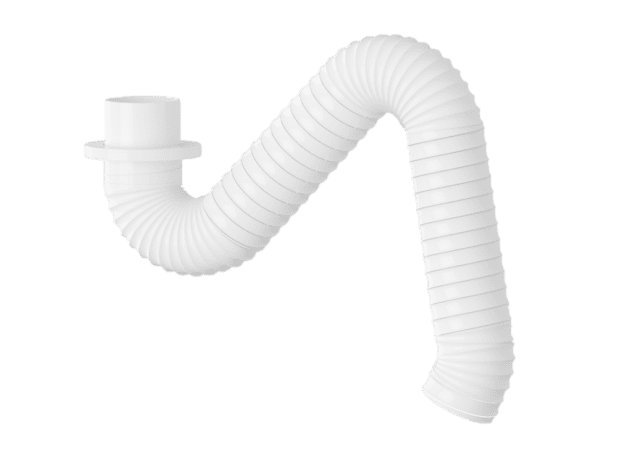

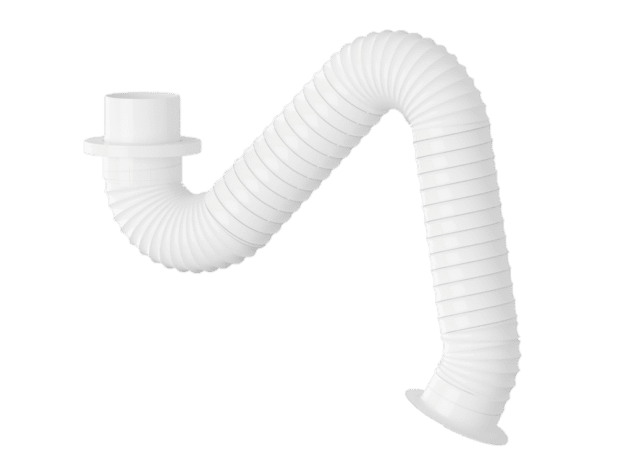

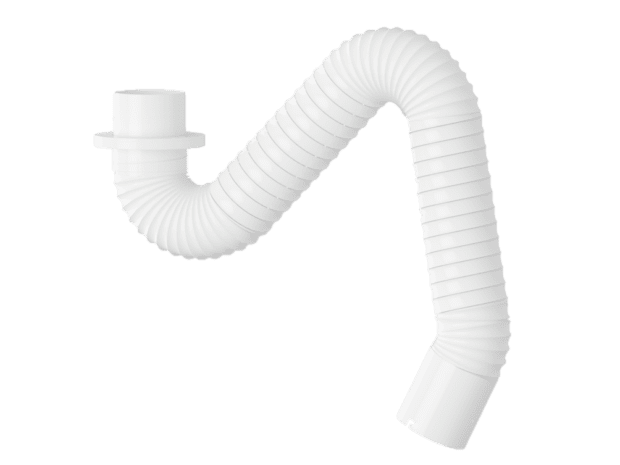

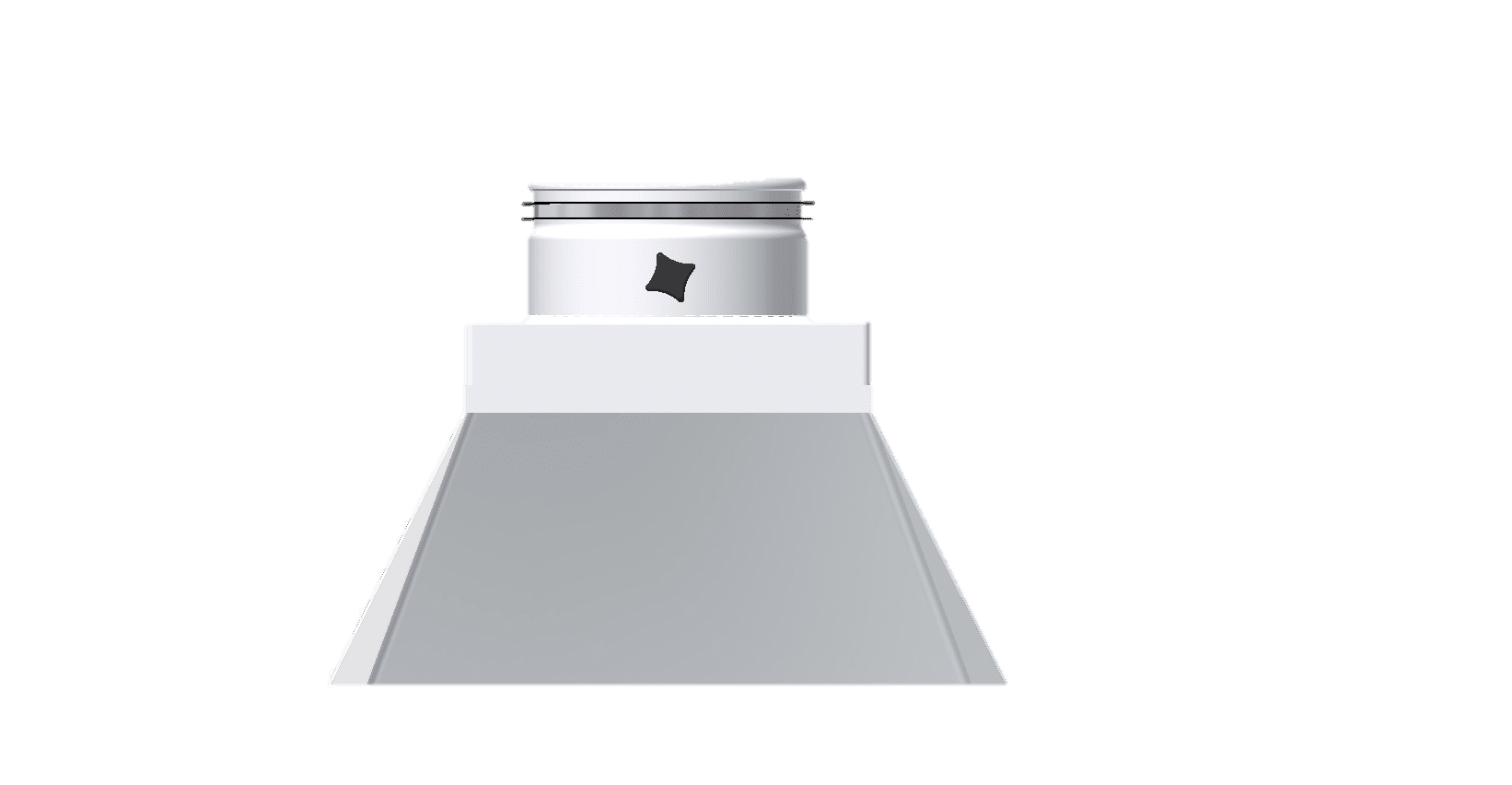

JPL – Extraction arm for ceiling mounting

Range 1050 mm, Dimension Ø 125, Swivel joint 360°

Product Description:

Flexible extraction arm for ceiling mounting. The extraction arm is suitable for extraction of smoke, dust, odours, vapours and gases by light chemical compounds and biological processes.

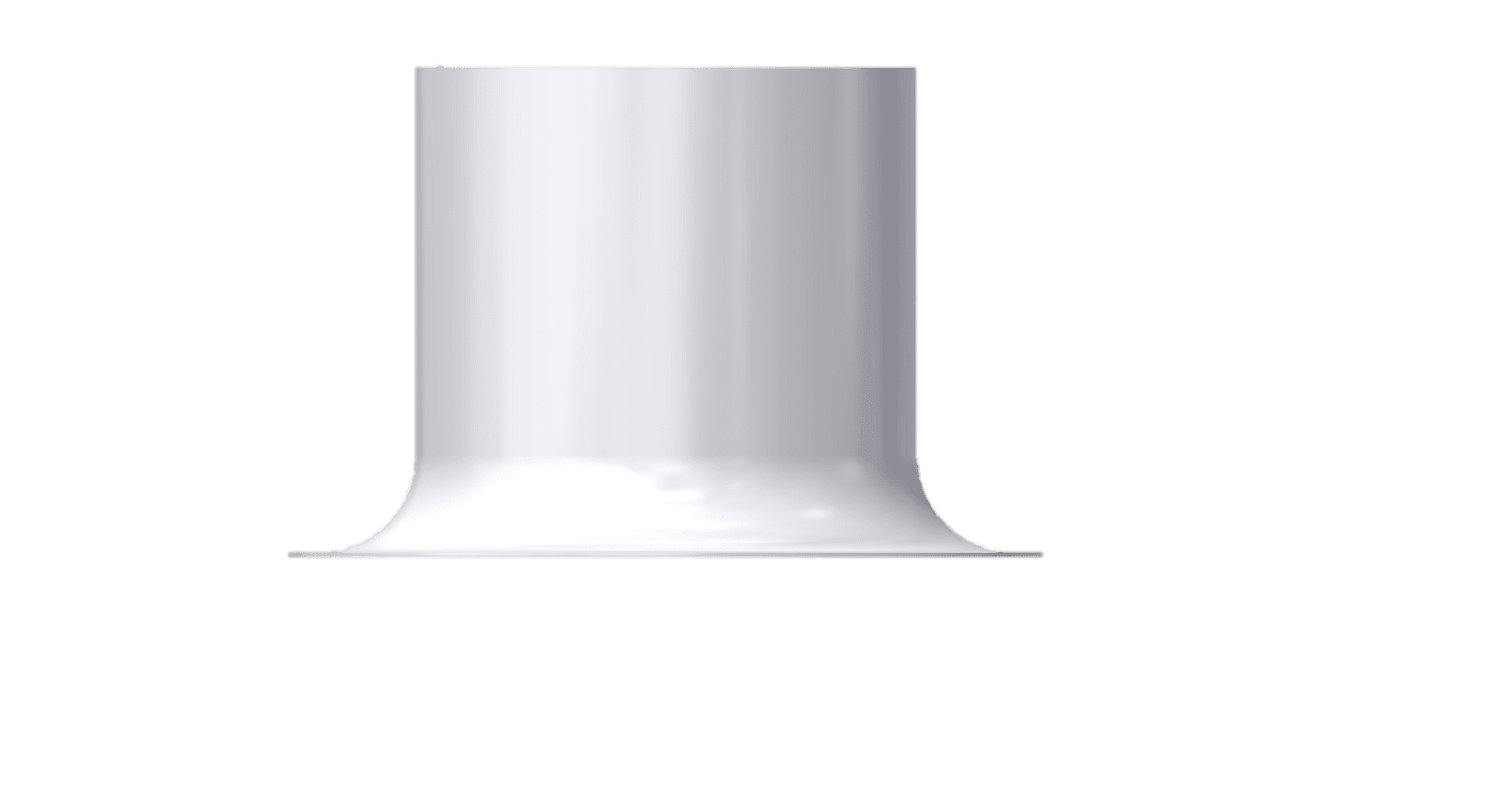

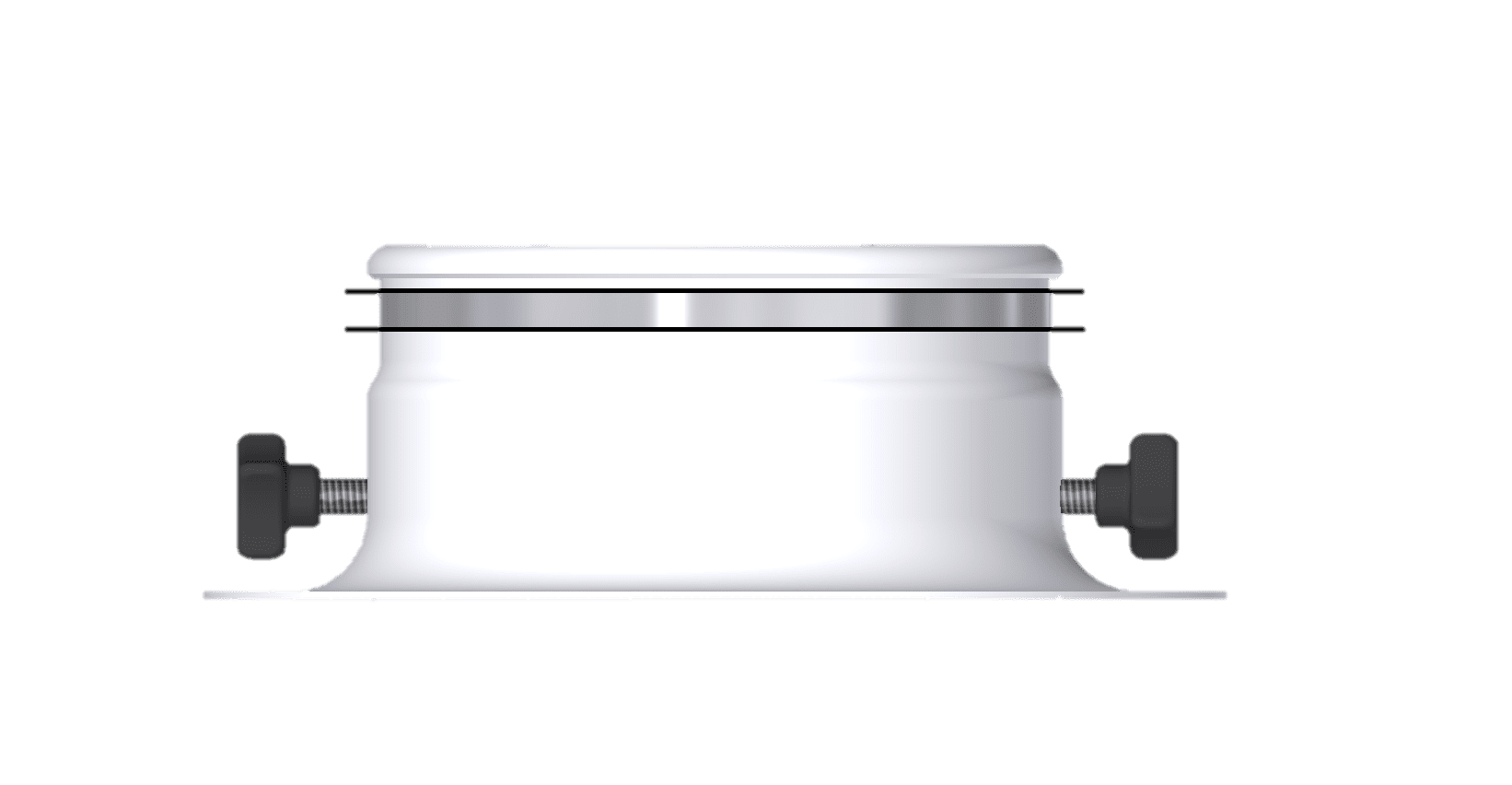

The extraction arm is mounted with 1 pc. 360° swivel at ceiling console. The 360 ° swivel joint is mounted a white flex hose with a length of 1000 mm, type flexible Combidec, and a internal breakable support arm in 3 joints with a unique braking function, this ensures maintenance of the extraction arm position. This provides a great deal of flexibility in the work process where the user can easily control the exhaust.

To optimize the suction capacity in relation to the given work function, the extraction arm can be mounted with a number of suction heads / suction screens and source filters. The extraction arm can be used in all workplaces with requirements for process ventilation.

Features and Benefits

- Suitable for extraction of smoke, dust, fume, gases and similar source of contamination

- Optimise personal protection

- Easy movement that provides flexibility in the work process

- Efficient braking function that ensures control of extraction at / over the process

- Has one of the lowest pressure losses on the market

- Large range of hoods, filter and accessories

- Easy to mount, maintain and clean

| Item no. | Dimension | Range / Swivel joint | Suction Hood | |

|---|---|---|---|---|

| JPL1000125360 | Ø 125 mm | 1050 mm / 360° | Without suction hood/br> |

| JPL1000125360STDH | Ø 125 mm | 1050 mm / 360° | With standard / funnel hood |

| JPL1000125360KOB | Ø 125 mm | 1050 mm / 360° | With coupling |

| Console / Pipe | Steel, white RAL 9016* |

| Internal support arm | White lacquered steel, brass and PE-HMW natural, extruded |

| Hose | White aluminum laminated plastic hose with steel spiral, Combidec |

| Strips / Clamps | Nylon |

| Hood | Plastic, PETG, Aluminium or Galvanized steel, white RAL 9016* |

* Available in gray RAL 7042.

** Can be delivered with Polyurethane flex hose.

| Item no. | Description | Item no. | Description | ||

|---|---|---|---|---|---|

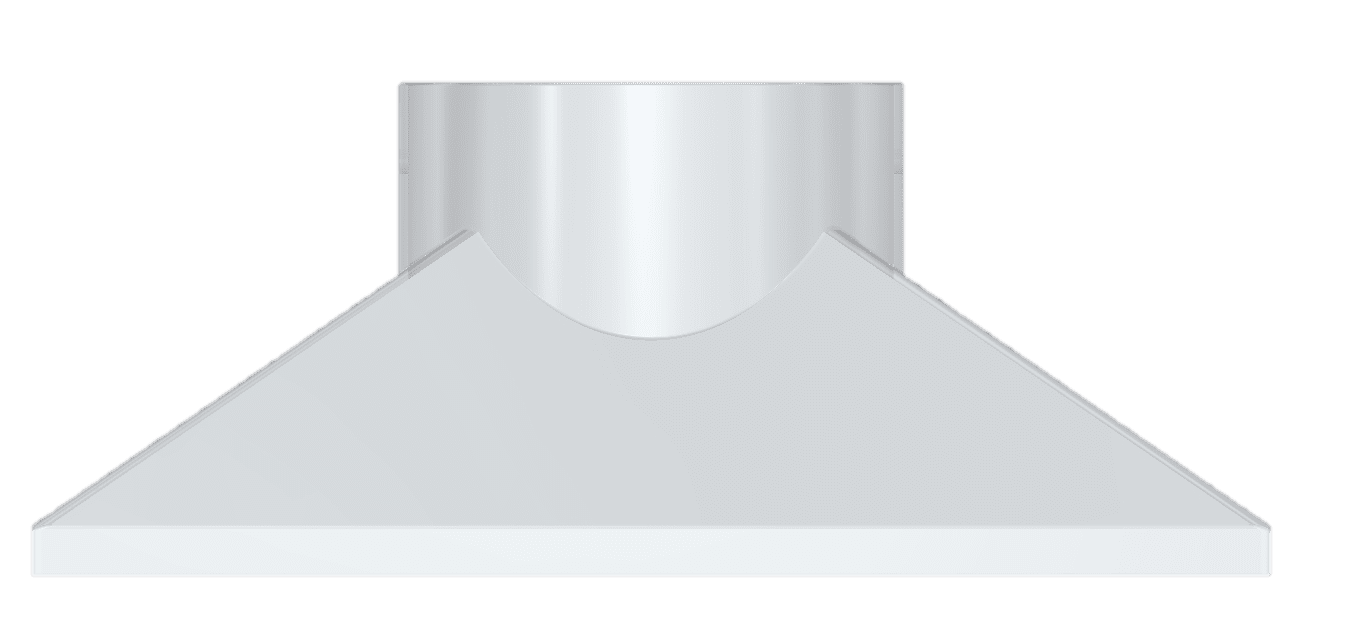

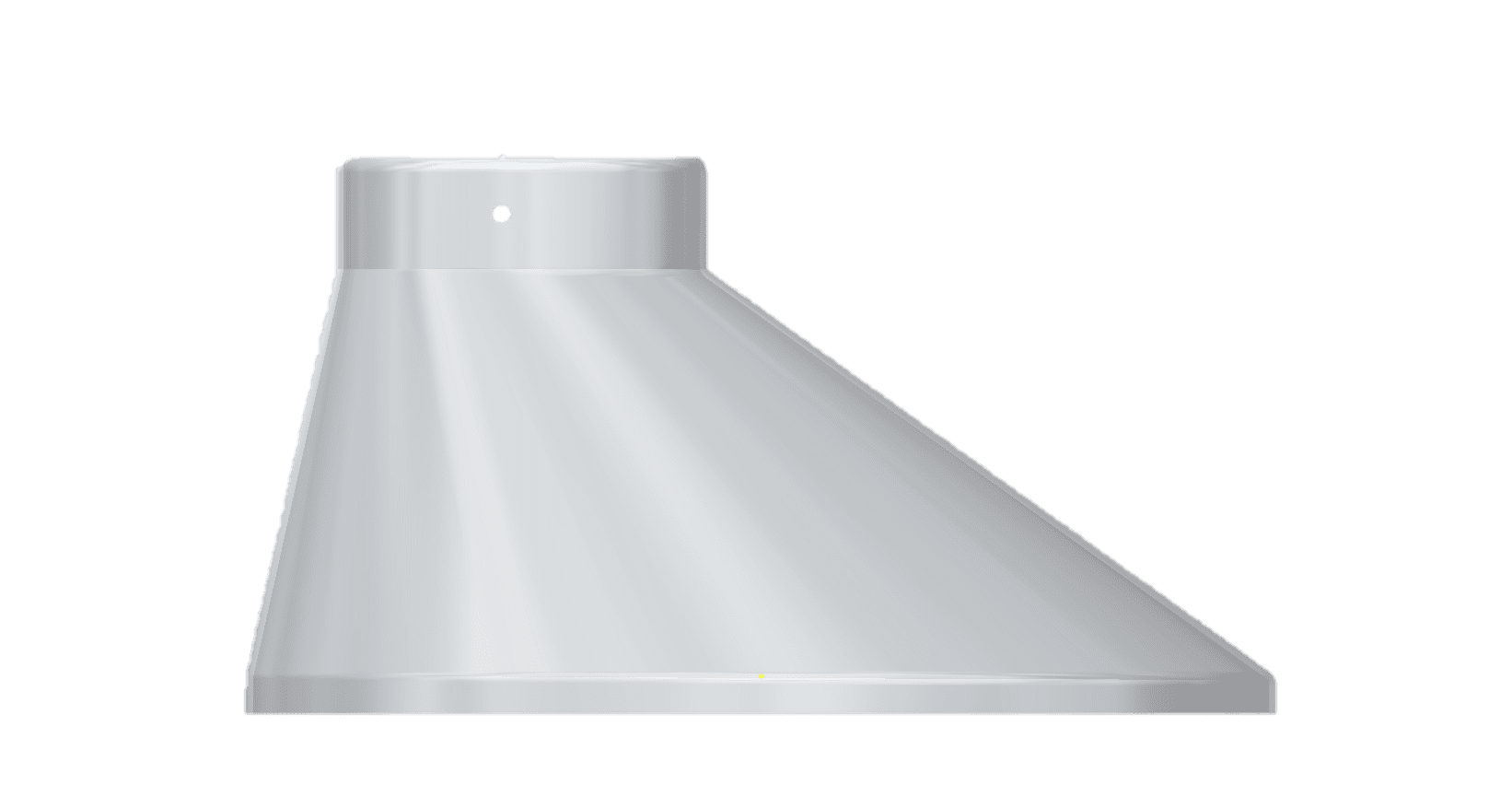

| POLY230360125F POLY230360125KOB | Rectangular Hood 230×360 mm PETG |  | ALU250125F ALU250125KOB | Funnel-shaped Ø 250 mm Aluminum, white RAL 9016 |

| POLY280125F POLY280125KOB | Eccentric Hood Ø 280 mm PETG |  | SUGH125F | Standard / Funnel Hood, white plastic |

| POLY250125F POLY250125KOB | Funnel-shaped Hood Ø 250 mm PETG |  | SUGH125KOB | Funnel Hood Galvanized steel, white RAL 9016 |

| POLY410125F POLY410125KOB | Dome-shaped Hood Ø 410 mm PETG |  | KOB125F | Coupling Galvanized steel, white RAL 9016 |

| POLY610125F POLY610125KOB | Dome-shaped Hood Ø 610 mm PETG |

KOB = Coupling, which makes it easy to switch between hoods using simple screws

| Item no. | Description | Used for filter | Item no. | Description | Used for filter | ||

|---|---|---|---|---|---|---|---|

| ALUKFL250125F ALUKFL250125KOB | Funnel-shaped Ø 250 mm Aluminium | F6 100x100x32 |  | POLYKFS410125F POLYKFS410125KOB | Dome-shaped Ø 410 mm PETG | F6 160x160x32 |

| 902102 | Source Filter F6 100x100x32 | Degree of filtration 60% |  | POLYKFS250125F POLYKFS250125KOB | Square 250×250 mm PETG | F6 160x160x32 |

| 902103 | Source Filter F6 160x160x32 | Degree of filtration 60% |

KOB = Coupling, which makes it easy to switch between hoods using simple screws

| Item no. | Description | Item no. | Description | ||

|---|---|---|---|---|---|

| SPJS125 | Damper |  | FLEX1000 | Inner, spare par |

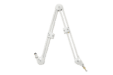

| 60530 | Pressure Guard |  | JPL125HJ | Bracing for ceiling console* |

| 60576 | Inductive Sensor |  | SLANGEH125 | White duct, Combidec |

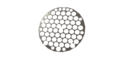

| NET125 | Net |  | SLANGEG125 | Grey duct, Combidec |

| OVS125 | Circular backflow |  | POLYS125 | White duct, Polyurethan |

Sizing Table

The measurements were performed in our test center in a 1 meter concole . The measuring point is located 6 times Ø from the point suction and in even air flow.| Dimension Ø 125 | Range 1050 – 360° | |||

|---|---|---|---|---|

| Air volume | m3/h | 200 | 250 | 300 |

| Pressure drop | Pa | 107 | 145 | 217 |

| Air velocity in duct | m/s | 4,5 | 5,6 | 6,7 |